More information about WAGNER and its products can be found at www.wagner-group.com Submit a Comment

WAGNER expands its range in the liquid coating sector with a manual Airspray gun that can do more than previously available models: The GM 1030P provides high-quality coatings with high class components – with efficient material consumption, versatile application possibilities, easy and fatigue-free handling and unrivaled low operating costs.

The new manual Airspray gun GM 1030P from WAGNER is not only highly precise in its application, but also extremely versatile. It is equipped with a nozzle which, with a maximum material passage of 9 mm, enables flexible processing of low to high viscosity materials with a high solids content. Depending on the application, a large number of air caps and nozzle sizes can be used. All components that come into direct contact with the coating material are made of durable stainless steel. Solvent-resistant gaskets, on the other hand, make it easy to use the gun with water- and solvent-based materials. The GM 1030P can be used for a variety of applications in many industries. It is suitable for the application of primers, fillers, clear lacquers or stains. Metal parts can be coated as well as furniture or plastic decorative elements.

Intelligent features support constant spray pattern and reduce overspray

The new development from WAGNER is also characterised by numerous details which are new to the market and which on the one hand reduce the material costs of the medium to be sprayed and on the other hand ensure a particularly uniform spray pattern. These features include setting the desired spray jet width with just one rotary knob. Once set, the air volume is automatically adjusted when the spray pattern changes from round to flat jet without having to readjust the atomizing air. “Spraying with too high atomizer air pressure is prevented, which reduces overspray by up to 15 percent and significantly lowers material costs”, explains Peter Neu, Senior Product Manager Industrial Solutions at WAGNER. The GM 1030P is equipped with a fixable needle stroke adjustment for process-safe coating with a constant material flow rate. This additionally optimises the material usage and has a positive effect on the application efficiency. The large material and air passages of the components also support perfect atomisation and at the same time permit a high application speed.

- GM 1030P hand gun

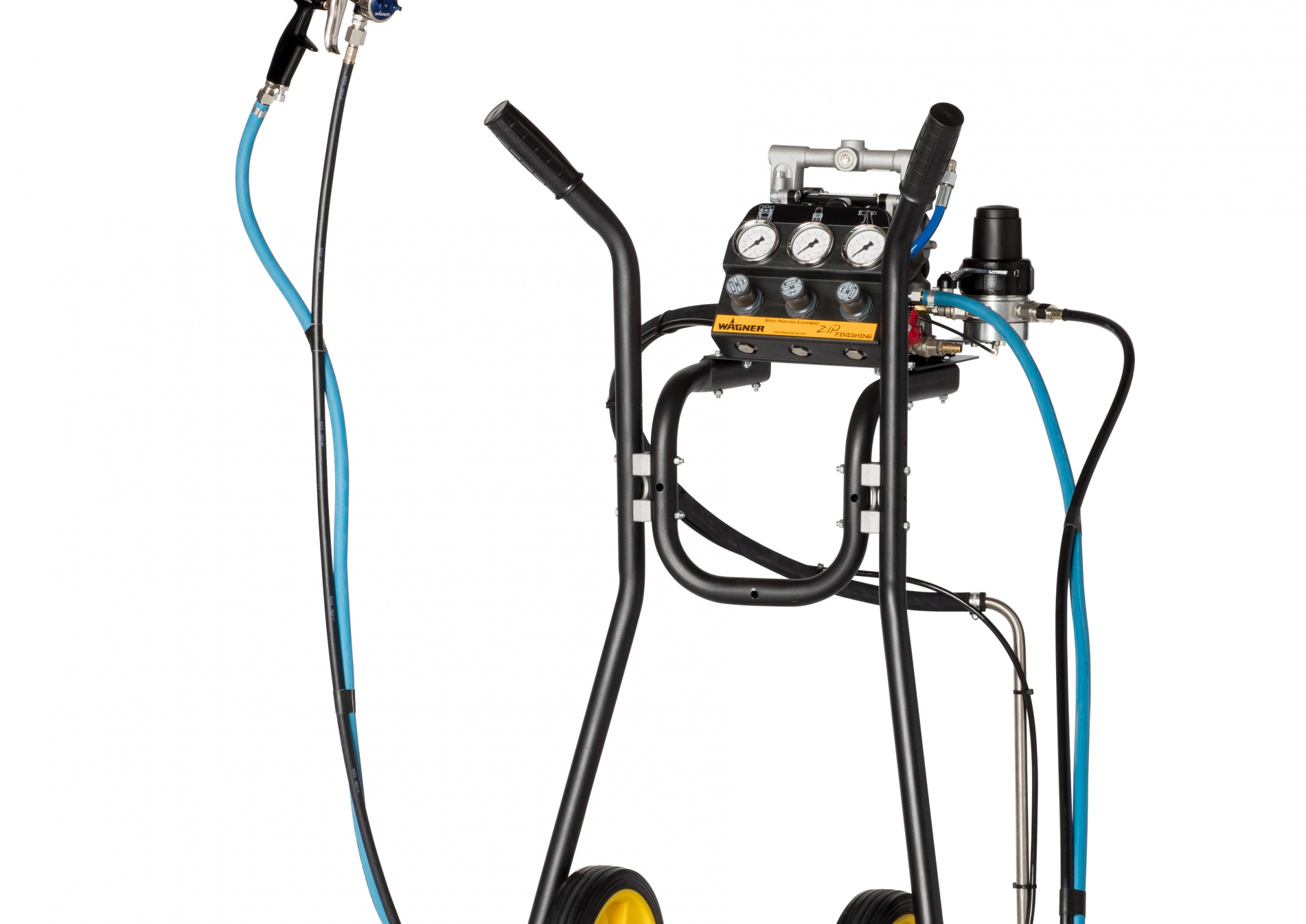

- GM 1030P Spraypack ZIP

- GM 1030P Spraypack DD10

- The product in action

Two-part nozzle for lower spare part and maintenance costs

Unlike comparable models, the new Airspray gun from WAGNER is equipped with a two-part nozzle consisting of nozzle head and nozzle nut. If necessary, it is sufficient to replace the nozzle head, which is considerably cheaper than replacing the complete nozzle and significantly reduces the cost of wearing parts. The reduced maintenance costs and minimal downtime of the gun are also due to long-life needles and the revised concept of the nozzle packing. This concept features an improved, highly resistant polyethylene seal. “Tests have shown that the nozzle packing of comparable guns leaks at a time when the new GM 1030P’s is still sealing perfectly for a long time,” reports Peter Neu. “The maintenance intervals of our Airspray gun are 40 percent longer, which means further cost savings.”

Practical design, easy handling

WAGNER has designed the Airspray gun in a particularly practical way: With the GM 1030P, the nozzle and needle size currently in use can be easily read from the outside. The gun does not have to be dismantled to identify a required spare part. This feature, as well as the use of durable, high-quality components, minimizes downtimes. The gun’s low weight and ergonomic design support fatigue-free work even over long periods of time. The anodised surface of the gun is also particularly easy to clean. In addition, the GM 1030P is available on request as a ready-to-spray spray pack together with hopper, suction hose and pump (TOPFINISH DD10 double diaphragm pump or Zip 52 low-pressure diaphragm pump).

More information about WAGNER and its products can be found at www.wagner-group.com