IoT Case Study: Transparent and enhanced management of the coating process @ Fox Laser with WAGNER’s COATIFY

Transparency of the powder coating process anytime and anywhere. With the COATIFY information and management platform, WAGNER fulfills this wish of a leading contract manufacturer in metalworking. The web-based system continuously provides relevant performance data of the coating system and raises awareness among the workforce for system utilization, cost reduction and highest quality in coating.

The challenge

Fox Laser Ltd is a leading contract manufacturer in the metalworking industry based in Sofia, Bulgaria which specializes in the production of high quality housing and profile components for renowned suppliers in the automotive, transport and switch cabinet construction sectors.

In the last for years, the company has experienced magnificent success leading to doubling of the workforce and increasing of capacity utilization. This growth required expansion of the production facilities to increase capacity which also applied to the company’s surface technology department that was brought up to date at the beginning of 2019. For this purpose a fully automatic WAGNER powder coating system with powder center, booth and ten automatic guns was installed.

The successful company development at Fox Laser requires the continuous hiring of new employees, who have to quickly familiarize themselves with the production facilities. At the same time, costs have to be continually optimized to ensure high production quality and competitiveness. In order to meet these versatile requirements, those responsible at Fox Laser wanted a comprehensive yet easy-to-use process control system for powder coating. The aim of the production manager was to keep an overview of the system anytime and anywhere and to know its status at all times.

The solution

In the planning phase for the new powder coating plant at Fox Laser, WAGNER Industrial Solutions launched the COATIFY information and management platform. This system exactly meets Fox Laser’s expectations for modern process monitoring.

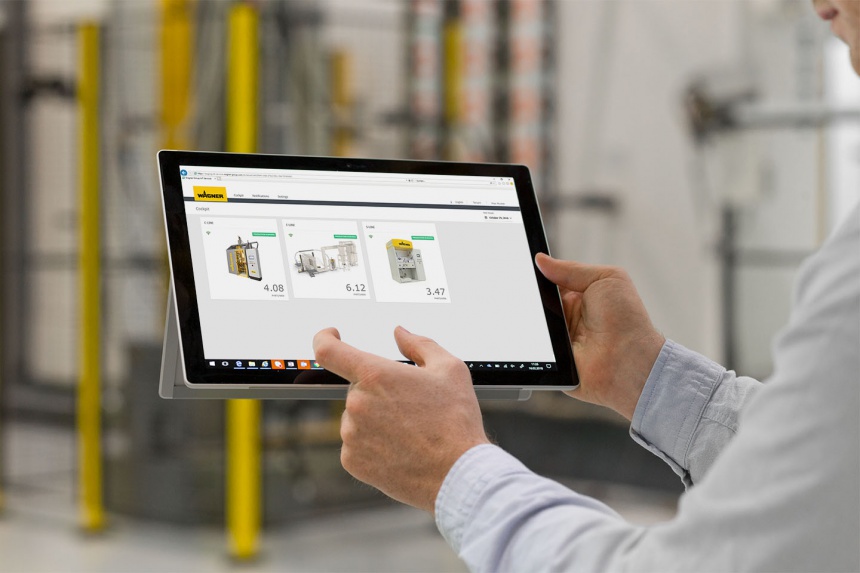

The web-based Internet of Things platform COATIFY visualizes the powder coating process intelligently and continuously. The system’s performance data can be captured at a glance on the clear user interface with descriptive diagrams and graphics. Relevant production data is easily prepared and logged, providing the user with a perfect overview of the process. The platform can be accessed via PC, tablet or smartphone and enables secure access to internal production data from anywhere.

“For us, COATIFY came at just the right time. With the continuous provision of important production data on various devices, we have the possibility to carry out an extremely reliable production monitoring. This improves process reliability and increases productivity,” says Dako Lisichkov, Managing Director at Fox Laser. Further, he is convinced that COATIFY is optimally equipped for the future with upcoming updates and new developments with regard to new coating solutions.

Digital interface: All the information in one tap

COATIFY at Fox Laser

https://youtu.be/NBdWPIzuhAM

The customer experience

After a short time COATIFY has already proven itself in operation at Fox Laser. Thanks to the clearly structured and graphically comprehensible system information, seamless monitoring of production is ensured at all times. Timely information on upcoming maintenance, malfunctions or deviations from individually definable limit values increase quality and system availability; thus, optimizing workflow and reducing costs.

Helpful feature of the application is that operators at Fox Laser can access the current operating manuals of the systems at any time via COATIFY. If a question cannot be answered on site, the customer sends a service ticket directly to WAGNER via COATIFY. This ticket provides system data and running times of the components electronically. If required, WAGNER service staff can also carry out remote maintenance.

“With COATIFY, we at Fox Laser now have full control over our coating quality and can intervene immediately if a parameter changes. This transparency increases process reliability, which will also have a positive effect on cost accounting,” Dako Lisichkov is convinced.

COATIFY optimally complements the coordinated components of the WAGNER powder coating system and thus makes powder coating even more efficient and economical. With COATIFY, WAGNER has created an industry solution with added value that raises production plants in surface technology to a new level in terms of economy, efficiency and process reliability.

For more information on COATIFY visit: https://www.wagner-group.com/en/industry/products/coatify-platform/

Source: https://www.wagner-group.com/en/industry/customerreferences/fox-laser/

Submit a Comment